How to deal with the bubbles generated by APET film?

APET film is believed to be unknown to everyone in life, but when it comes to high-end blister packaging, cartons, and windows, its application is indispensable. Like many films, APET must pay special attention to details during production. Only good products can make consumers trust and promote the capital of long-term cooperation. So how to deal with the bubbles in the compounding process of APET films? If there is a problem, it will not only affect the appearance, and have a great impact on later sales.

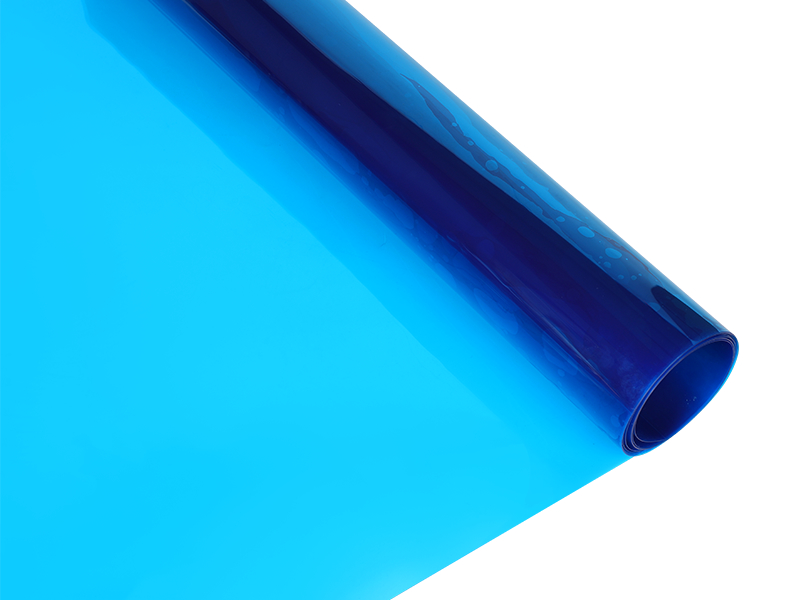

APET film

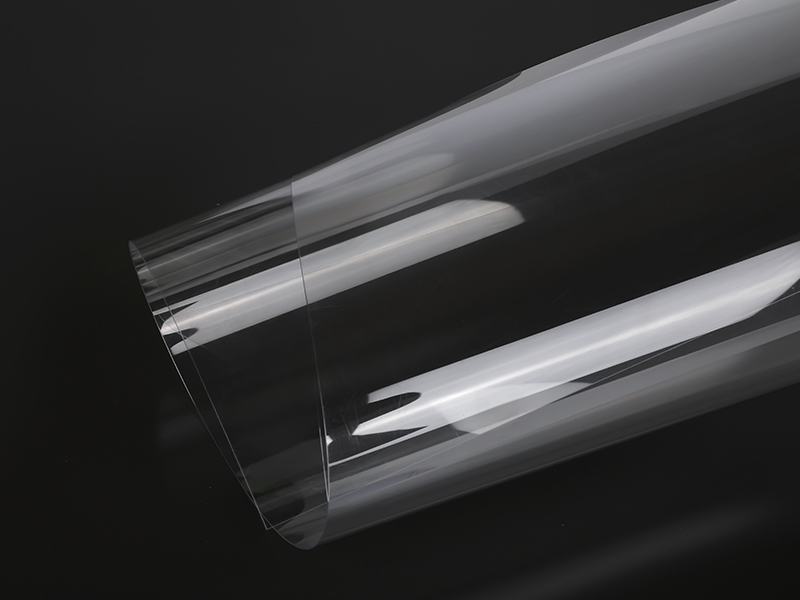

If it is a hard point APET film protective film, if it is a bubble, it can be seen through careful observation before you compound it. This is due to the production process and other reasons when producing the PET film protective film, and it cannot be processed further. If you have a special test tool, the thickness of the bubble point is not the same as in other places.

There are many reasons for hard spots (transportation in the early stage, production process, subsequent processing, etc.) If there is no problem with the film in the early stage, then you must pay attention to the smoothness of the roller during the subsequent processing. You can feel the roller by touching it with your hands. smoothness. If the hardness of the rubber pressure roller is too high, the air pressure of the pressure roller can be adjusted appropriately. In addition, it is caused by impurities being brought into the roller, which is often ignored.

English

English Español

Español