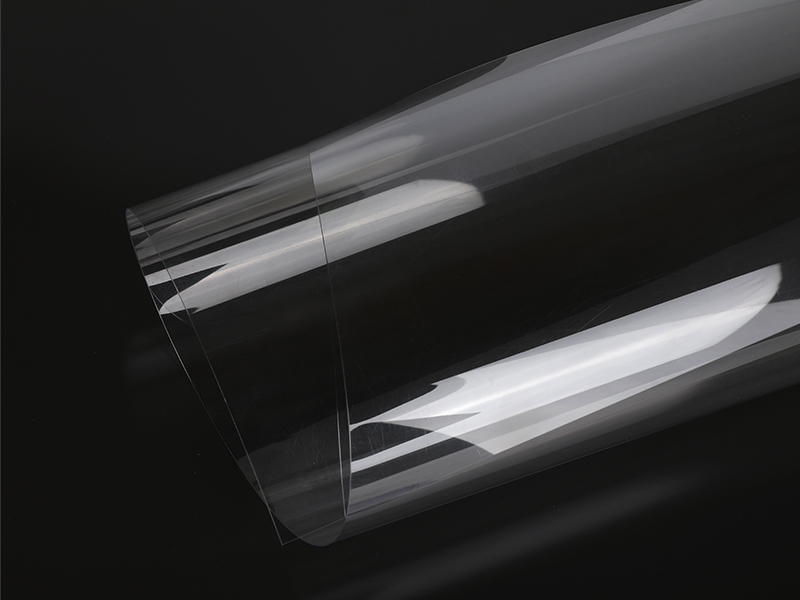

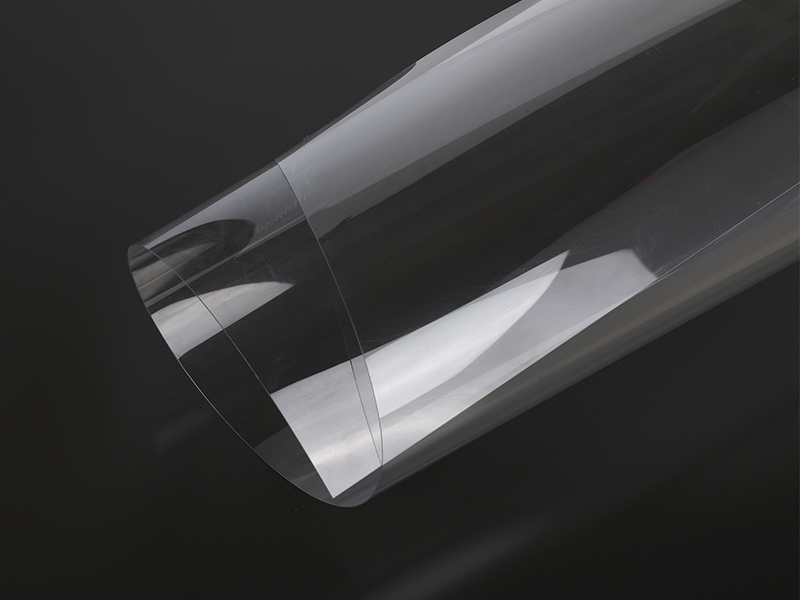

Features: High stiffness, hardness, toughness, good impact strength, food-grade materials

product

CONTACT

- Tel : +86-188-67921717

- Mobile : +86-198-58927700

- Email : [email protected]

[email protected] - Address : No.2, Duhu Road, Xiaying Industrial Zone, Anwen Town, Pan'an County, Zhejiang, China.

PETG Plastic Sheets Film Rolls Manufacturers

Features: High stiffness, hardness, toughness, good impact strength, food-grade materials

About us

Established in 2006, Zhejiang ZhongSheng New Materials Co., Ltd. has a registered capital of $11.21 million and a manufacturing area of 40,000 square meters. It is one of the professional PETG Plastic Sheet/Film Manufacturers and Transparent PETG Sheets/Film Factory. Our annual capacity is 70,000 tons of polymer sheet, which includes PETA, PETG, and PET-GAG, and is used for thermoforming, vacuum forming, blister packing, and furniture decorative film panels. After 16 years of development, we are leading in the PET polymer sheet industry and has strong competitiveness with more than 60 patents inventions and applications. Our self-developed PETG film are extensively used in furniture decoration panels and has quickly occupied the domestic market as well as the foreign market. We can offer PETG Sheet/Film.

OUR NEWS

-

Use PET Plastic Rolls To Enhance Product Protection And Display

Sale Cheap Transparent PET Plastic Film Rolls Sheet Price In the competitive world of retail and packaging, businesses are constantly seeking innovati...

Read More + -

PET Plastic Rolls Provide Strength And Clarity To Your Products

China Wholesale PET Plastic Sheet PETG Rolls Maker In the packaging industry, the choice of material can significantly impact the quality and appeal o...

Read More + -

The Evolution of PET Sheet Film

Sale OEM PET Sheet Panels Film Suppliers The PET Sheet Film, a product of the polymer industry, has undergone a remarkable evolution since its incepti...

Read More + -

The Advantages of PET Sheet Film in Food Packaging and Beyond

China Custom PET Card Transparent Sheets Film Manufacturer In the modern era of packaging, PET Sheet Film has emerged as a pioneer material due to its...

Read More + -

Understanding the Durability and Clarity of PET Sheet Film

Custom OEM Transparent PET Plastic Rolls Sheet Film in China In the realm of packaging materials, PET Sheet Film stands out as a versatile and high-pe...

Read More + -

The Role of PET Sheet Film in Enhancing Product Visibility

Wholesale Cheap White PET Mylar Sheet Film Price In the competitive world of retail and product display, the use of PET Sheet Film has become a strate...

Read More +

English

English Español

Español