How does the thickness of APET sheet APET film affect its performance and suitability for different applications?

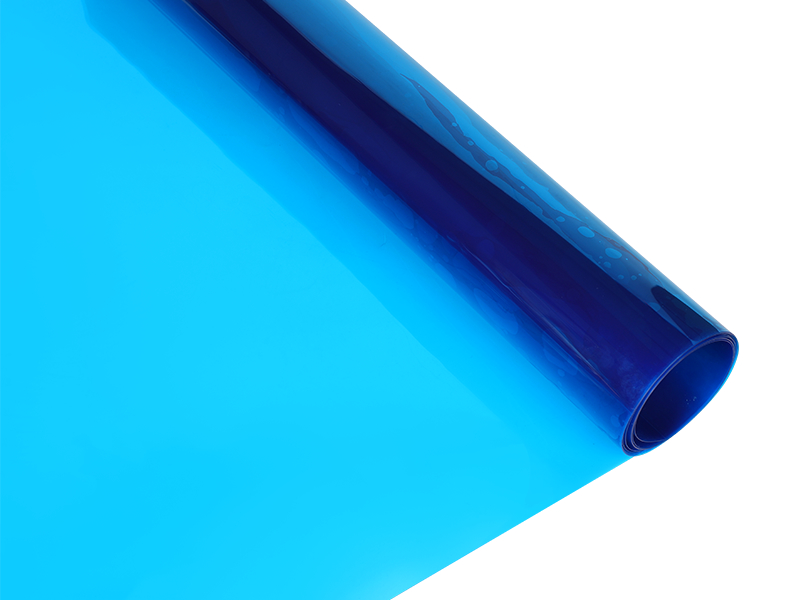

The thickness of APET sheet/film can have a significant impact on its performance and suitability for different applications. Thicker sheets/films generally provide more stiffness and durability, making them suitable for applications that require high strength and resistance to impact or puncture, such as clamshell packaging, thermoformed trays, and blister packaging.

On the other hand, thinner sheets/films are more flexible and can conform to the shape of the product being packaged, making them suitable for applications such as lidding films and food packaging. Thinner films are also typically more cost-effective than thicker films, which can make them a preferred choice for high-volume applications.

However, it is important to note that the performance of APET sheet/film is not solely determined by its thickness. Other factors such as the quality of the material, the manufacturing process, and the specific requirements of the application can also impact its suitability and performance. Therefore, it is essential to carefully consider all of these factors when selecting the appropriate thickness of APET sheet/film for a given application.

How does the recyclability of APET sheet APET film compare to other types of plastic packaging materials, and what initiatives are in place to promote its sustainability?

APET sheet/film is considered to be one of the most recyclable types of plastic packaging materials. It is a thermoplastic polymer that can be easily melted down and reprocessed into new products. Compared to other types of plastic packaging materials, such as PVC or polystyrene, APET has a higher recycling rate and can be recycled more times without losing its quality.

Initiatives to promote the sustainability of APET sheet/film include increasing the availability of recycling facilities and educating consumers on the importance of recycling. Many companies are also implementing sustainable packaging practices by using recycled APET and reducing the amount of material used in their packaging.

In addition, some companies are exploring alternative materials that are even more sustainable than APET. For example, some are using bio-based plastics made from renewable resources, or compostable materials that can break down naturally without harming the environment.

How does APET sheet/film perform under different environmental conditions, such as temperature and humidity, and what precautions need to be taken to ensure its integrity?

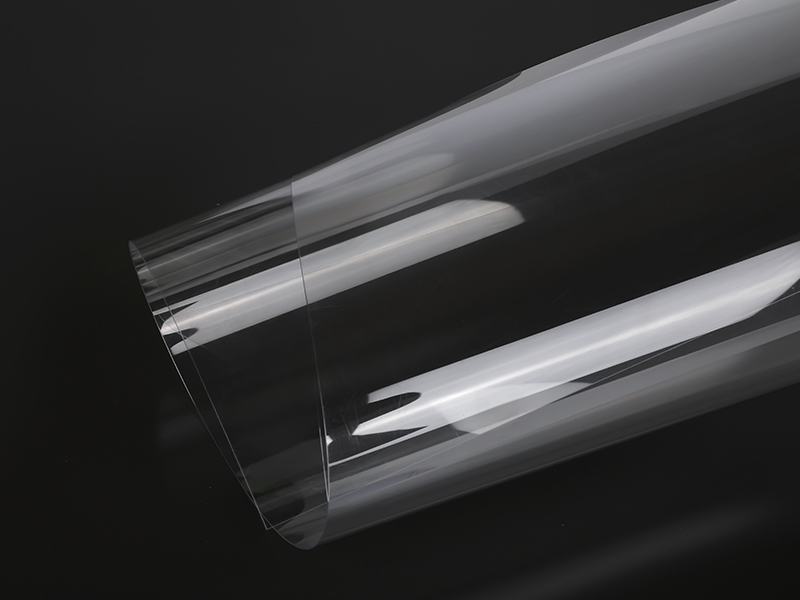

APET sheet/film is a highly versatile material that performs well under a wide range of environmental conditions. However, its performance can be affected by temperature and humidity.

At low temperatures, APET sheet/film can become brittle and lose its flexibility, making it more prone to cracking or breaking. At high temperatures, it can soften and lose its dimensional stability, which can cause warping or distortion.

Humidity can also impact the performance of APET sheet/film. In high-humidity environments, the material can absorb moisture and become more flexible, which can make it more difficult to handle and process. In low-humidity environments, the material can become static and attract dust or other contaminants, which can affect its appearance and cleanliness.

To ensure the integrity of APET sheet/film under different environmental conditions, several precautions can be taken. For example, storage and handling conditions should be carefully controlled to minimize exposure to extreme temperatures or humidity. During processing or fabrication, appropriate temperatures and humidity levels should be maintained to ensure consistent performance and quality. Additionally, any packaging made from APET sheet/film should be designed to protect the contents from changes in temperature or humidity that could affect their integrity or shelf life.

English

English Español

Español