Navigating Thermoplastic Possibilities: An In-depth Exploration of APET, PETG, and GAG Sheets in Corporate Applications

Author: admin / 2023-12-15

High quality APET Sheet, China PETG Sheet, GAG Sheet price, APET Sheet for sale, PETG Sheet factory

In the ever-evolving landscape of industrial materials, thermoplastics have emerged as pivotal elements for various applications. Among these, APET (Amorphous Polyethylene Terephthalate) Sheet, PETG (Polyethylene Terephthalate Glycol) Sheet, and GAG (Glycol-Modified Amorphous Polyethylene Terephthalate) Sheet stand out for their unique characteristics and diverse applications. In this comprehensive overview, we will delve into the distinct qualities of each thermoplastic sheet, examining their corporate applications and providing a comparative analysis to assist businesses in making informed decisions.

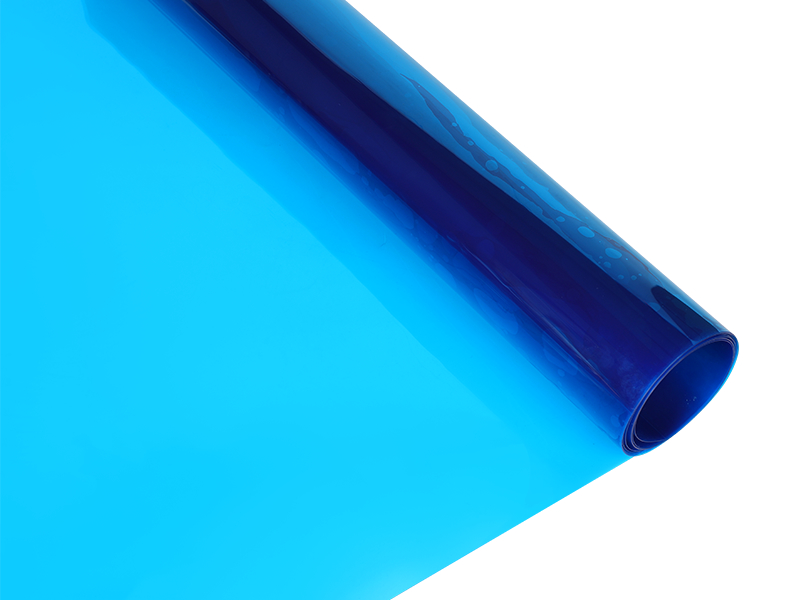

APET Sheet:

APET Sheet, known for its clarity, strength, and versatility, has found widespread use in diverse industries. From a corporate perspective, APET Sheets are commonly employed in packaging applications where transparency and impact resistance are paramount. In the food industry, for instance, APET Sheets are ideal for creating clear packaging that showcases the freshness and quality of the contents. Additionally, their chemical resistance makes them suitable for packaging applications in the pharmaceutical and medical sectors, ensuring the integrity of sensitive products.

The corporate world also benefits from the use of APET Sheets in graphic arts, providing a durable and clear substrate for printed materials. APET's dimensional stability makes it suitable for applications like signage, retail displays, and promotional materials, where maintaining visual integrity over time is crucial.

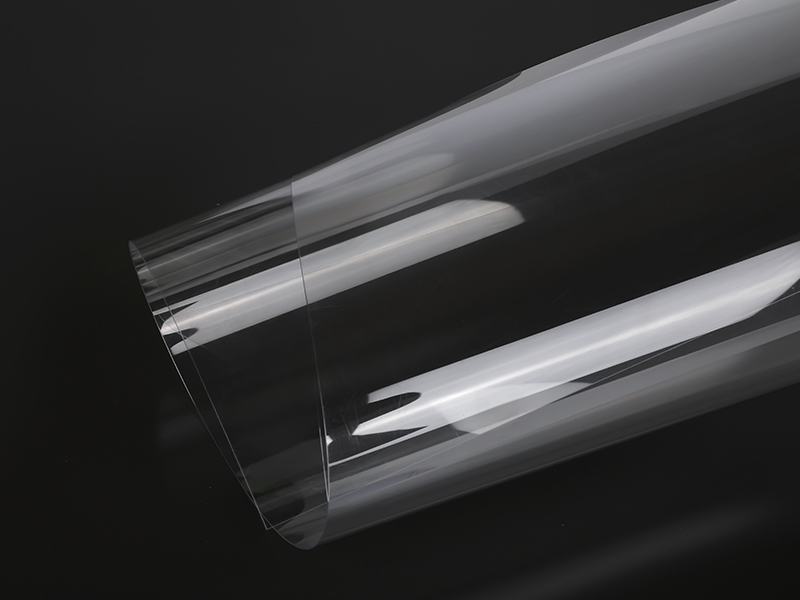

PETG Sheet:

PETG Sheet, distinguished by its exceptional impact resistance, chemical resistance, and easy thermoforming capabilities, offers a wide range of applications in the corporate sector. In packaging, PETG Sheets excel when durability and visibility are both critical factors. Their impact resistance makes them suitable for protective packaging of delicate items, such as electronics or high-end consumer goods. The clarity of PETG Sheets ensures that products remain visible, enhancing the overall consumer experience.

Corporate applications extend to industries where hygienic and easy-to-clean surfaces are essential, such as medical equipment and point-of-sale displays. PETG's ability to undergo intricate thermoforming processes makes it a good choice for manufacturing detailed components and enclosures in industries ranging from automotive to electronics.

GAG Sheet:

GAG Sheet, or Glycol-Modified Amorphous Polyethylene Terephthalate, combines the desirable characteristics of PETG and APET. From a corporate standpoint, GAG Sheets find applications where a balance between clarity, impact resistance, and processability is required. This makes GAG Sheets suitable for industries that demand both visual appeal and structural integrity, such as consumer electronics packaging or high-end retail displays.

GAG Sheets can be thermoformed into complex shapes, providing flexibility in design without compromising on performance. Their chemical resistance makes them suitable for packaging applications in various sectors, including cosmetics and personal care, where maintaining product integrity is crucial.

Comparative Analysis:

When comparing APET, PETG, and GAG Sheets, several key factors come into play, including clarity, impact resistance, chemical resistance, and processability. APET excels in providing optical clarity and chemical resistance, making it suitable for applications where transparency and product integrity are essential. PETG, with its superior impact resistance and thermoforming capabilities, is favored in industries that require durable packaging and intricate components. GAG Sheets, combining features from both APET and PETG, offer a balanced solution for applications that demand clarity, impact resistance, and processability.

In terms of corporate applications, APET Sheets find their niche in industries where visual appeal and chemical resistance are paramount. PETG Sheets shine in applications that require robust impact resistance and thermoforming versatility. GAG Sheets, bridging the gap between APET and PETG, cater to industries seeking a well-rounded solution that balances clarity, impact resistance, and processability.

Conclusion:

In the realm of thermoplastics, APET, PETG, and GAG Sheets each bring a unique set of qualities to the corporate table. The choice between them depends on specific requirements, ranging from the need for optical clarity and chemical resistance to superior impact resistance and thermoforming capabilities. By understanding the distinct attributes of these thermoplastic sheets, businesses can strategically integrate them into their packaging, manufacturing, and design processes, harnessing the versatility of thermoplastics to enhance their corporate applications and meet the evolving demands of their industries.

English

English Español

Español