We are still developing

As people's quality of life continues to improve, the requirements for product appearance and design are also getting higher and higher. PETG decorative boards/films and PET sheets/films, as two widely used decorative materials, are meeting this demand. Although these two materials are both polyester plastics, they present completely different performance characteristics due to different chemical structures and production processes.

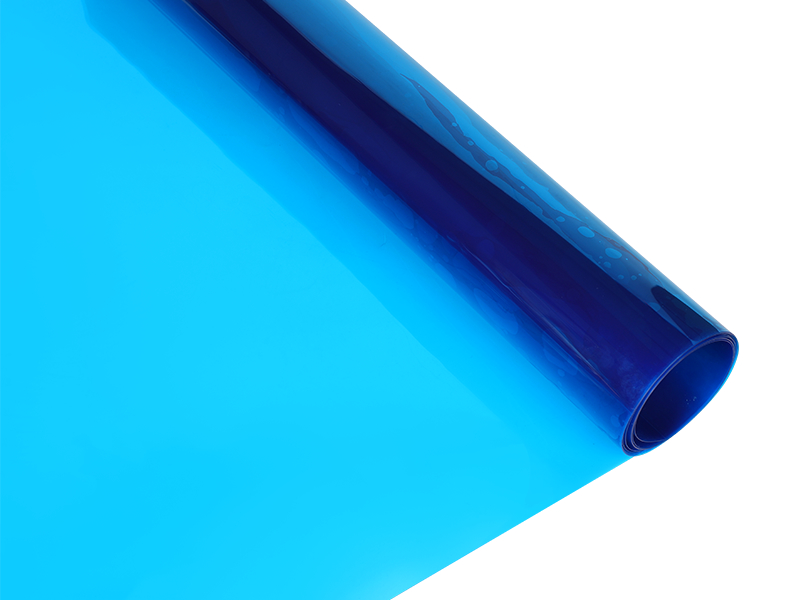

1. PETG decorative board/film

PETG, the full name of polyethylene terephthalate, is a modified polyester material. Compared with ordinary PET materials, PETG has the following outstanding performance characteristics:

1. Excellent thermoforming performance

PETG material has a low glass transition temperature, usually between 75-85°C, which gives it excellent thermoforming properties. PETG decorative panels/films can quickly soften and form after being heated, and can quickly cool and solidify after forming to maintain the desired appearance and shape. This excellent thermoforming performance makes PETG decorative boards/films widely favored in home appliances, furniture and other fields.

2. Good heat resistance

The heat resistance of PETG material is better than that of ordinary PET, and the maximum use temperature can reach 80-100℃. This allows the PETG decorative board/film to maintain good appearance and performance within a certain temperature range, and is suitable for occasions that need to withstand a certain amount of heat.

3. Excellent chemical resistance

PETG material has excellent chemical resistance and can resist the erosion of a variety of acids, alkalis, oils and other chemicals. This enables PETG decorative boards/films to perform well in home appliances, furniture and other fields and maintain their appearance for a long time.

4. High transparency and gloss

PETG material has good optical properties, with a transparency of more than 90%, and it can also provide excellent gloss effects. This enables PETG decorative boards/films to bring excellent visual effects to products and meet consumer demand for the appearance of high-end products.

5. Environmentally friendly and non-toxic

The PETG material itself is non-toxic and harmless, and does not release harmful substances during production and use, complying with environmental protection requirements. This makes PETG decorative boards/films very popular in home, furniture and other fields.

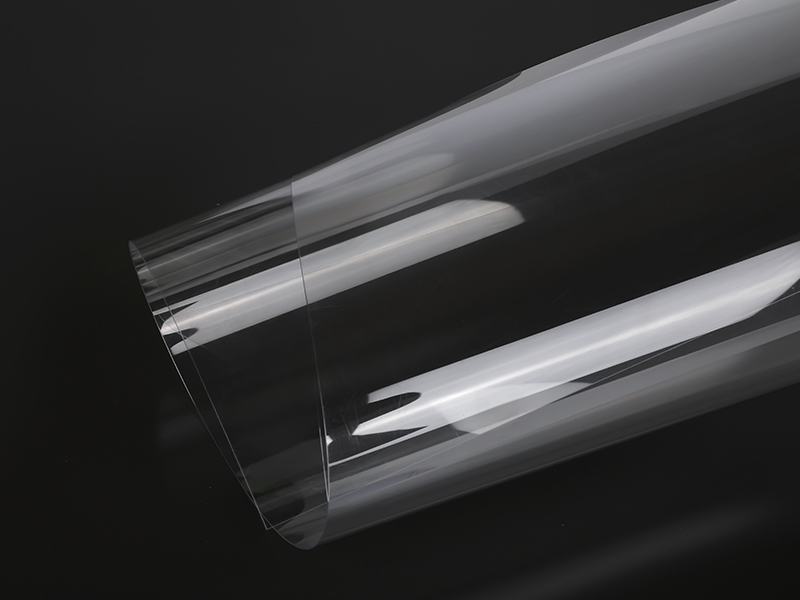

2. PET sheet/film

PET, the full name of polyethylene terephthalate, is a general-purpose polyester material. Compared with PETG, PET sheet/film has the following unique performance characteristics:

1. Excellent transparency

PET material has excellent optical properties and the transparency can reach more than 90%. This makes PET sheets/films widely favored in fields such as optics and electronics.

2. High rigidity and chemical resistance

PET material has good rigidity and chemical resistance, and can effectively resist the erosion of chemicals such as acids, alkalis, and oils. This enables PET sheets/films to excel in packaging, electronics and other fields.

3. Excellent dimensional stability

PET material has excellent dimensional stability and can effectively inhibit thermal shrinkage and deformation. This makes PET sheets/films popular in precision optical components, electronic components and other fields.

4. Good heat resistance

The maximum operating temperature of PET material can reach 100-150℃, which is better than ordinary plastic. This allows PET sheet/film to maintain good performance within a certain temperature range.

5. Environmentally friendly and non-toxic

The PET material itself is non-toxic and harmless, and does not release harmful substances during production and use, complying with environmental protection requirements. This makes PET sheets/films popular in packaging, electronics and other fields.

3. Development trends of PETG decorative boards/films and PET sheets/films

As consumers' demands for product appearance and performance continue to increase, PETG decorative boards/films and PET sheets/films have broad application prospects. In the future, the development trends of these two materials are as follows:

1. Continuous performance optimization

As materials science continues to advance, the performance of PETG and PET materials will be further optimized. For example, the heat resistance and chemical resistance of PETG may be further improved, and the transparency and dimensional stability of PET may also be further improved. This will lay the foundation for the application of these two materials in a wider range of fields.

2. Continuous expansion of application fields

As the properties of PETG and PET materials continue to be optimized, their application areas will also continue to expand. For example, PETG decorative boards/films may be further used in automotive interiors, medical equipment and other fields, and PET sheets/films may also be further used in new displays, flexible electronics and other fields.

3. Environmental protection performance continues to improve

As society pays increasing attention to environmental protection, the environmental performance of PETG and PET materials will continue to improve. For example, it is possible to develop more environmentally friendly and non-toxic PETG and PET materials, or to achieve efficient recycling of these two materials. This will further promote the widespread application of these two materials in various fields.

In general, PETG decorative boards/films and PET sheets/films are being widely used in home appliances, furniture, automobiles, packaging, optics, electronics and other fields due to their excellent performance characteristics. With the continuous advancement of materials science, the application prospects of these two materials will be broader, and they will surely provide better products and services for various industries.

English

English Español

Español