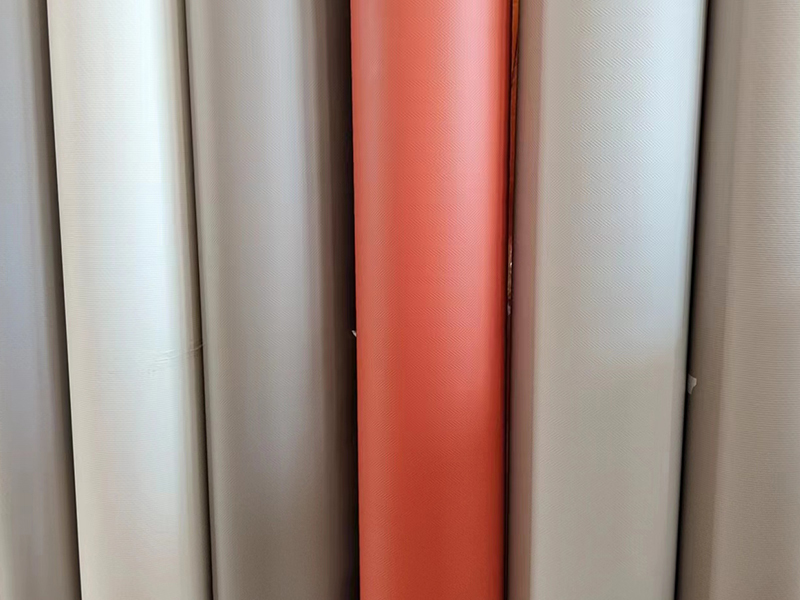

What are the main applications of PETG decorative sheet/film in the interior design industry?

Wall panels: PETG decorative sheet/film can be used to create attractive and durable wall panels that can withstand impacts and abrasions. They are commonly used in high-traffic areas such as hospitals, schools, and commercial buildings.

Furniture: PETG decorative sheet/film can be used to create a variety of furniture pieces such as chairs, tables, and cabinets. It can be formed into intricate shapes and designs to create unique and eye-catching furniture.

Retail displays: PETG decorative sheet/film is commonly used to create retail displays, such as product shelves, display cases, and signage. It can be formed into different shapes and sizes and printed with custom graphics to match a specific brand image.

Lighting: PETG decorative sheet/film is used to create decorative lighting fixtures, such as diffusers and lenses, which can create a range of lighting effects.

Partitions: PETG decorative sheet/film can be used to create partitions that provide privacy while allowing natural light to pass through. These partitions are commonly used in offices and other commercial settings.

Decorative accents: PETG decorative sheet/film can be used to create decorative accents such as moldings, trims, and other decorative elements. It can be printed with custom graphics or patterns to match a specific design theme.

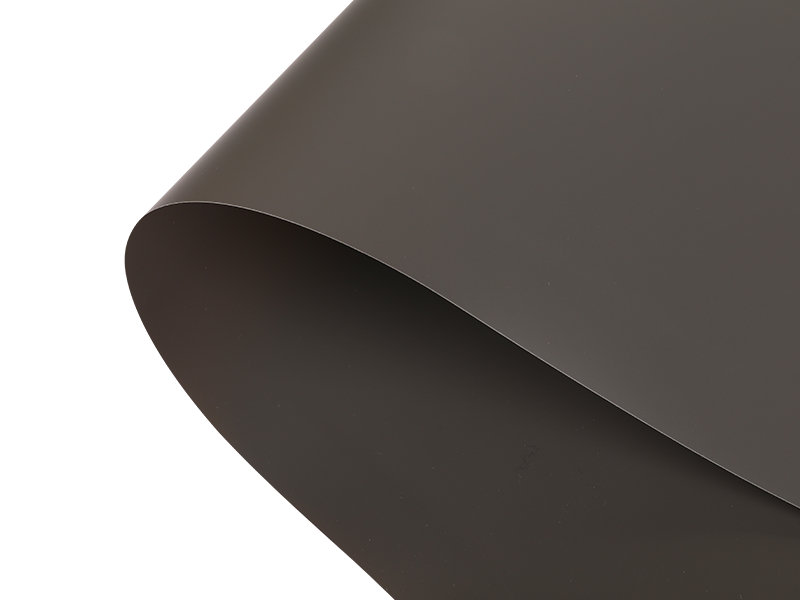

What are the key properties of PETG decorative sheet/film that make it superior to other plastic films in terms of durability and impact resistance?

High impact resistance: PETG decorative sheet/film has excellent impact resistance, which means it can withstand impacts without cracking or breaking. This makes it ideal for use in high-traffic areas or applications where it may be subjected to rough handling.

Chemical resistance: PETG decorative sheet/film is resistant to many chemicals, including acids and alkalis. This makes it ideal for use in environments where it may be exposed to chemicals, such as laboratories or manufacturing facilities.

Scratch resistance: PETG decorative sheet/film has a hard surface that resists scratching, which helps to maintain its appearance over time. This is particularly important in applications where the surface may be exposed to abrasive materials, such as furniture or retail displays.

UV resistance: PETG decorative sheet/film has good UV resistance, which means it can be used in outdoor applications without yellowing or degrading over time.

Clarity and transparency: PETG decorative sheet/film has excellent clarity and transparency, which makes it ideal for use in applications where visual aesthetics are important. It also allows for better light transmission, which is important in lighting applications.

Easy to fabricate: PETG decorative sheet/film can be easily cut, formed, and fabricated using standard techniques, such as thermoforming or CNC routing. This makes it a popular choice for custom applications and prototypes.

What are the environmental considerations associated with the production and disposal of PETG decorative sheet/film?

Raw material sourcing: PETG decorative sheet/film is made from petrochemicals, which are non-renewable resources. The extraction and processing of these resources can have negative impacts on the environment, such as air and water pollution, habitat destruction, and climate change.

Energy consumption: The production of PETG decorative sheet/film requires significant amounts of energy, which contributes to greenhouse gas emissions and climate change.

Waste generation: PETG decorative sheet/film production generates waste materials, such as scrap and offcuts, which can contribute to environmental pollution if not properly managed.

Recycling: PETG decorative sheet/film is recyclable, but the recycling process can be complex and costly. Recycling also requires energy and can result in waste generation if not properly managed.

Disposal: PETG decorative sheet/film can end up in landfills if not recycled or properly disposed of. In landfills, it can take hundreds of years to degrade, contributing to environmental pollution and greenhouse gas emissions.

To minimize the environmental impact of PETG decorative sheet/film, it is important to consider the following strategies:

Reduce raw material consumption by using recycled PETG or other sustainable materials.

Optimize production processes to reduce energy consumption and waste generation.

Implement effective waste management and recycling programs to minimize waste and maximize recycling.

Properly dispose of PETG decorative sheet/film at the end of its life cycle to prevent it from ending up in landfills.

English

English Español

Español